Engineers provide planning for every step of a heavy lift project. They work with draftsmen, estimators, and customers all along the way. Engineers are responsible for getting the crane to the job site, designing a lift plan, and providing operators all of the information they need to perform the job safely and efficiently.

When preparing for a job, engineers must take into account several aspects, including:

- Crane Location

- Clearance Issues

- Rigging Designs

- Outrigger Loadings

- Support Surface Analysis

- Crane Mat Design

Let’s take a closer look at what a quality engineer must contemplate before every job.

Crane Location

This could include how the crane gets to the job, where the crane is placed, and how to assemble the crane if necessary. No two jobs are ever similar in this regard, as an experienced engineer could be working with a crowded downtown street or in the middle of a 300-acre field.

Each has their advantages and disadvantages, and an engineer will take in all of that information when planning. Everything from blocking off roads, removing power lines, to the inspection of the ground surface at the location must be considered. Getting permits and cooperation from local officials if necessary are all part of the job.

Clearance Issues

Once the crane is in place, how much room does it have to operate? The engineer will let you know. This includes the jib length, boom length, and turning radius of the crane. Engineers take into account obstacles above, below, and to the side while planning a lift.

Even working on a wind turbine in the middle of nowhere, clearance is an issue. Is there a trailer on site or will a secondary crane be needed? A site audit is needed for every site, no matter where that site may be.

Rigging Designs

When lifting several tons of material hundreds of feet in the air, the potential for disaster is high. With a well-planned rigging design from the engineer, this risk is reduced dramatically. Finding the load center of gravity, determining weight, and establishing rigging points are just a few factors to be considered.

The name of the game is safety. This means the appropriate amount of weight is being loaded, a safety zone established, pinch points identified, and more. This protects crane operators, riggers, people on the ground, and materials being lifted.

Outrigger Loadings

Providing additional stability for the crane, outriggers are called into practice for certain jobs. However, there’s more to it than just pulling them out and setting them in place. Depending on the situation, there is no guarantee the weight of the crane and load will be evenly distributed to the outrigging.

The engineer will calculate the load table for each outrigger for every job. The potential force on each outrigger must be established so the crane has stable footing. An unstable foundation leads to an unstable – and unsafe – lift.

Support Surface Analysis

So much of the planning happens with the crane, surrounding areas, and load positions. Nearly all of that information is useless if the ground itself isn’t taken into account. Will the crane be used on a city road, thick concrete slabs, or bare dirt? How much weight each surface can support must be accounted for.

The engineer will do a site analysis to make sure there is stable footing for the cranes. If there isn’t, the engineer must devise a plan to turn any instability into a solid foundation.

Crane Mat Design

To help with surface support, crane mats are often called into service. Placed under outriggers or the crane itself, these mats must be designed to provide stability as well as disbursing force to the surface. Surface area, thickness, and even material are all part of the equation with crane mat design.

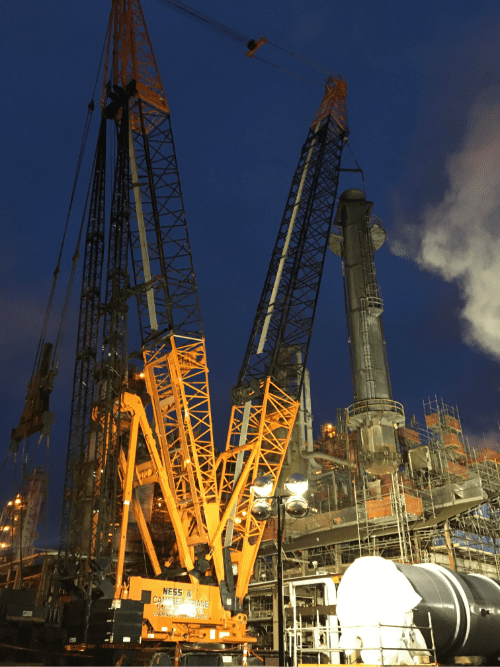

Many firms concentrate on just one aspect of the lift. They provide the cranes, deliver the cranes, or operate the cranes. With NessCampbell, we handle every phase of the project. At NessCampbell, we use in-house engineers that are highly qualified and experienced. That way we know the engineered designs for a project are expertly handled every step of the way.

Have a big job in the Pacific Northwest that involves heavy hauling, lifting, and engineered planning? Reach out to NessCampbell today. We hire the most experienced engineers and provide the highest quality lifting plans in the industry. We look forward to hearing from you!